Ensuring compliance and maintaining quality are crucial aspects of dimensional inspection equipment’s role in regulatory adherence. Organizations can ensure their products meet the necessary standards through dimensional inspection equipment by implementing robust inspection procedures and fulfilling regulatory requirements.

The dimensional accuracy of components or products can be found through inspections using precise measurement tools and techniques. Additionally, regular audits and reviews of inspection processes can aid in identifying any gaps or areas for improvement, guaranteeing continuity of compliance and quality assurance.

Dimensional Inspection Equipment

Dimensional Inspection equipment is commonly used in manufacturing and quality control processes to ensure that products meet the required specifications. Some common types of dimensional inspection equipment include the following:

Height Gauges: Height gauges measure the vertical distance between a reference surface and a specific point on an object.

Coordinate Measuring Machines (CMM): CMMs are advanced measuring systems that use a probe to measure the dimensions of an object in three-dimensional space.

Optical Comparators: Optical comparators use a light source and a projection screen to magnify and compare the dimensions of a part with a reference template.

Laser Scanners: Laser scanners use laser beams to capture the surface profile of an object and create a 3D digital model.

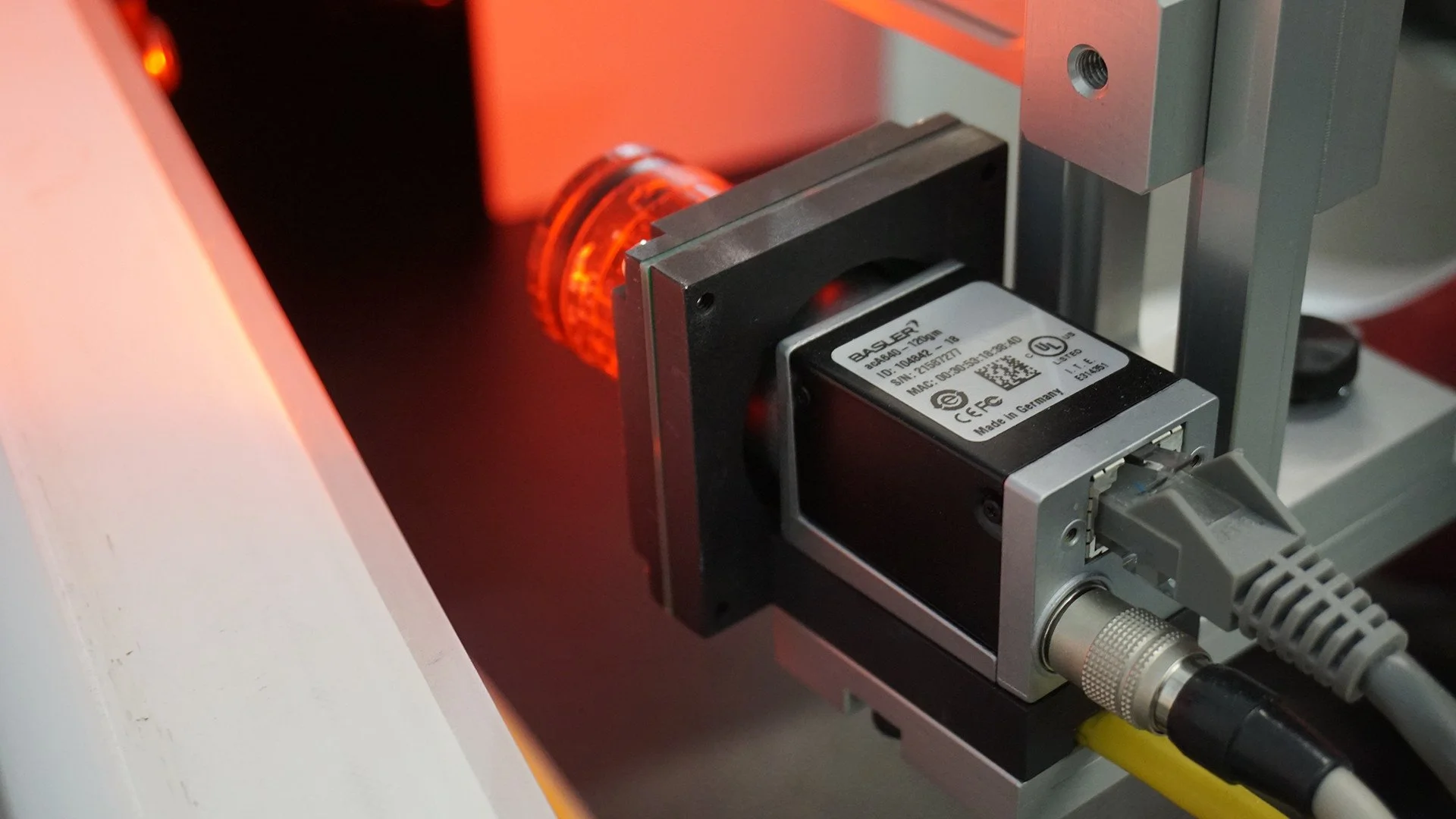

Vision Systems: Vision systems use cameras and image processing algorithms to inspect and measure the dimensions of objects. They are often used in automated inspection processes and can detect defects and deviations from the required specifications.

Complying with Regulatory Adherence

Reducing risk and liability is crucial in risk management, and dimensional inspection equipment helps lower the liability risk. By conducting product or component testing before manufacturing, you can proactively identify and resolve issues, preventing costly and potentially disastrous consequences. Whether it is assessing the roundness of a precision bearing or the curvature of a bolt's interior thread root, precise measurements can determine the line between failure and success.

Effective decision-making increases through advanced measurements. What may seem like a promising process or product on paper may not translate well in reality. By utilizing measurements during the development stage, you can make informed decisions before it's too late to make necessary changes.

Determining process capability is essential, especially for products exposed to extreme conditions such as high pressure, force, or shear. Conducting a capability study before subjecting the process or equipment to these conditions can save significant time and money. Regulatory compliance is a critical aspect of many industries. Dimensional inspection equipment helps with compliance and quality assurance, allowing for a proactive and cost-effective approach.

The role of dimensional inspection in regulatory adherence necessitates a strong focus on compliance and quality assurance. In achieving this, organizations establish comprehensive protocols and procedures that align with regulatory requirements. This includes employing skilled inspectors with a deep understanding of dimensional measurement techniques and can accurately interpret and analyze inspection data.

By implementing a systematic approach to dimensional inspection, organizations can mitigate the risk of non-compliance and ensure that their products consistently meet the required standards, ultimately enhancing customer satisfaction and maintaining a strong reputation in the industry. Contact us today to learn more about dimensional inspection services and their role in regulatory compliance.