Implementing machine learning is a game-changer across industries, altering how we collect and analyze data, automate processes, and make decisions. By utilizing the power of algorithms that harness and learn from data, machine learning allows systems to examine their constituents without instruction and expand their comprehensive capabilities.

Automated Inspection Systems

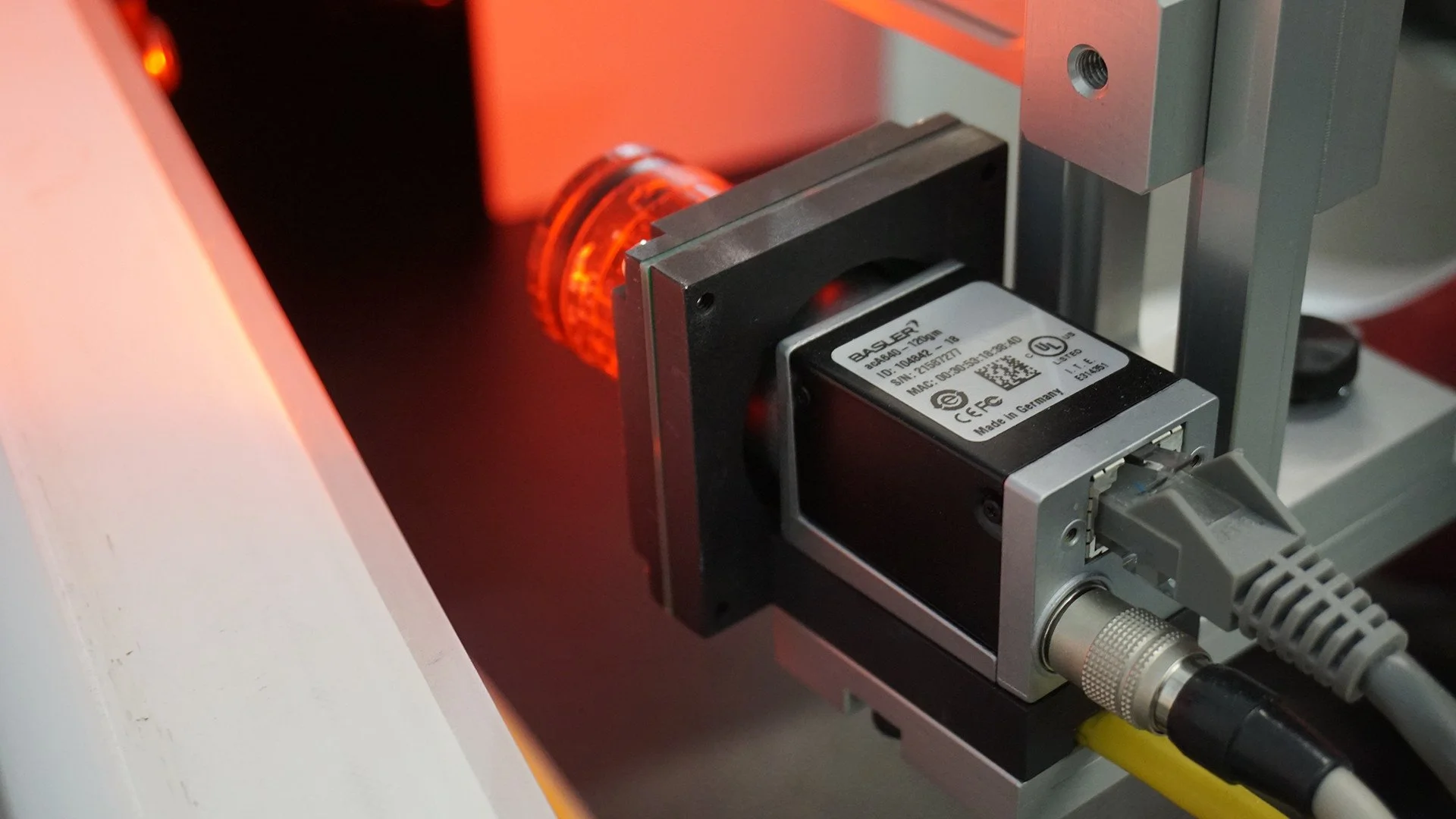

Automated Inspection Systems (AIS) are advanced technological solutions that enhance quality control processes across multiple platforms. By integrating progressive imaging technologies, software algorithms, and robotics, these systems can perform detailed inspections of products or components at high speeds with astounding accuracy. AIS works to expedite the manufacturing and packaging processes but also ensures consistency and compliance with strict quality standards. AIS minimizes human error, reduces operational costs, and improves overall efficiency, making it a vital asset in today’s fast-paced production domain.

Automated Inspection Systems Dimensions

The dimensions of AIS equipment are crucial in maximizing the facility's workable areas. Compact and efficient designs are highly valued and aim to accommodate the needs of various systems, including conveyors, robotics arms, and cameras. The precise space arrangement within these systems ensures accuracy and reliability in detecting defects or deformities, allowing for the upkeep of quality control standards.

AIS Production Time Frame

Decreasing cycle time yields remarkable results regarding reducing costs and improving product quality. Our systems allow for a broader range of data collection, allowing for more scanning of surfaces in a shorter amount of time. Efficient automated systems remove the need for excess labor, allowing conservation of time and money.

Inspection Team’s Expertise

Our inspection team can evaluate systems to ensure they meet the strict requirements of ISO-9001, QS-9000, TS-16949, and the Fastener Quality Act policies. Our capabilities include utilizing advanced diagnostic tools and techniques to assess the condition and safety of structures and machinery accurately. Our experts are proficient at providing detailed reports and suggestions, which are vital for maintaining compliance, optimizing production, and protecting the integrity of products.

Benefits of Automated Inspection Systems

Many benefits follow from integrated automated inspection systems into your operations, including the following:

Error-proofing

Speed & Efficiency

Redeployment of staff

Data trending & analysis

The integration of machine learning through the use of AIS has revolutionized the way businesses operate. It has provided companies with powerful tools that collect and analyze data, automate processes, improve decision-making, and elevate customer satisfaction. This industry will continue to expand and be transformed by the integration of machine learning, allowing businesses to be well-equipped for continual success.