At Mectron Inspection, we know that finding flaws in metal parts without damaging them is a big deal in industries like aerospace, automotive and manufacturing. That’s where our patented Eddy Current Testing Machine comes in. This powerful tool uses electromagnetic fields to spot cracks, corrosion and other hidden defects, keeping equipment safe and operations running smoothly.

In this blog, we’ll break down how eddy current testing works, the science behind it and where it’s used most. Whether you're new to nondestructive testing (NDT) or just curious about the technology, we’ll make it easy to understand.

The Science Behind Eddy Current Testing

Eddy current testing is based on electromagnetic induction, the same principle that makes wireless chargers and metal detectors work. Here’s how it happens:

A coil inside the machine carries an alternating current (AC), creating a magnetic field around it.

When this coil gets close to a conductive material (like metal), the magnetic field induces swirling electrical currents (called eddy currents) inside the material.

Flaws in the material disrupt these currents, changing the magnetic field’s behavior.

The machine detects these changes, revealing cracks, thinning or corrosion without touching or harming the part.

Since different metals and flaws affect eddy currents in unique ways, the machine can identify problems based on signal patterns.

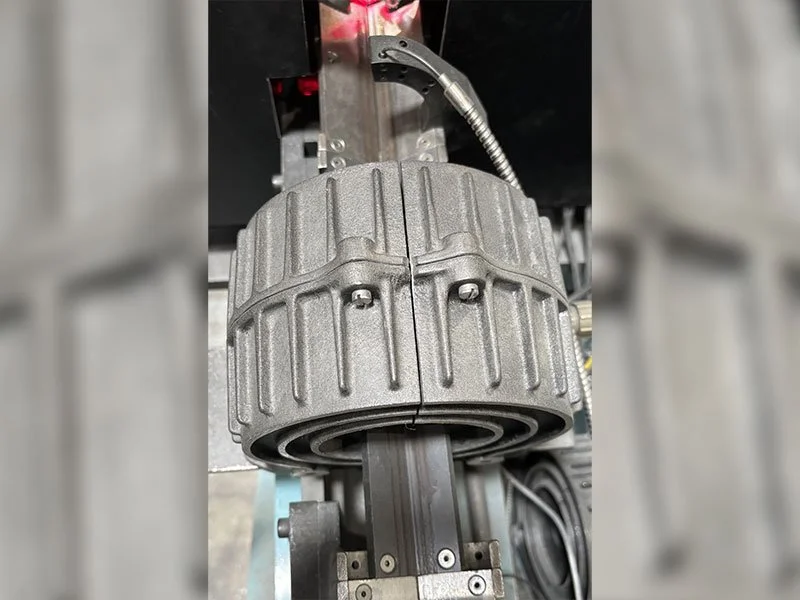

How an Eddy Current Testing Machine Works

An eddy current testing system has a few key parts:

Probe (Coil): The handheld or automated sensor that generates and measures eddy currents.

Oscillator: Produces the alternating current that powers the coil.

Signal Processor: Analyzes changes in the eddy currents to detect flaws.

Display/Output: Shows results as graphs, charts or alarms for inspectors.

When the probe scans a metal surface, it sends real-time data to the processor. If there’s a crack or defect, the signal shifts, alerting the operator. Some machines can even measure material thickness or coating layers.

Where Eddy Current Testing Shines: Key Applications

Because it’s fast, versatile and doesn’t require direct contact, eddy current testing is used across many industries.

1. Aerospace & Aviation

Checks aircraft components (engine blades, landing gear, fuselage) for fatigue cracks.

Inspects heat-exchanger tubes for corrosion.

2. Automotive Manufacturing

Tests suspension parts, welds and bearings for hidden flaws.

Verifies the quality of electric vehicle battery components.

3. Oil & Gas

Monitors pipelines and storage tanks for wall thinning.

Examines drill rods and valves for stress cracks.

4. Railways & Infrastructure

Scans train wheels and tracks for wear and fractures.

Evaluates bridge cables and structural steel.

5. Medical Devices & Electronics

Ensures surgical tools and implants are defect-free.

Tests circuit boards and heat sinks for irregularities.

Unlike X-rays or ultrasound, eddy current testing doesn’t need liquids or radiation, making it safer and easier for many inspections.

Advantages of Eddy Current Testing

No surface prep needed: Works through paint, coatings and dirt.

Fast results: Scans parts in seconds, ideal for high-volume production.

Works on complex shapes: Can inspect tubes, curved surfaces and tight spaces.

Detects tiny flaws: Finds hairline cracks and early-stage corrosion.

However, it only works on conductive materials (metals) and may struggle with deep subsurface flaws. For those cases, other NDT methods like ultrasonic testing might be better.

Why Choose Mectron Inspection for Eddy Current Testing?

At Mectron Inspection, we design and supply eddy current testing machines that meet strict industry needs. Our equipment is built for clarity and ease of use, helping inspectors make confident decisions. Whether you’re in aerospace, energy or heavy manufacturing, we have solutions to keep your operations safe and efficient.