In fastener manufacturing, heat treating is the essential step that gives metal parts their strength and durability. But when this process doesn't go as planned, the results can be problematic. Issues like uneven hardness, material flaws or incorrect tempering can quickly undermine a fastener's performance. This can lead to failures in everything from automotive assemblies to aerospace systems. For manufacturers in Taiwan and beyond, addressing heat treat-related defects is a must for maintaining product integrity and customer trust.

At Mectron Inspection Systems, we understand the nuances of heat treat verification. Basic inspection can miss the small flaws that heat treating can cause. Our method is different. We use specialized technology built to find these specific defects early, preventing expensive mistakes down the line. In fact, every sorter we make comes equipped with our own Mectron-built differential coil, made specifically for the task of hardness sorting and verifying heat treatment. This isn’t an add-on; it’s built into the core of our systems, providing a layer of scrutiny that goes beyond surface-level checks.

The Heat Treat Challenge in Fastener Production

Heat treating involves controlled heating and cooling processes to alter a fastener’s mechanical properties, such as hardness and strength. However, variations in time, temperature or quenching can cause inconsistencies. For example, under-hardened fasteners might lack the required strength, while over-hardened ones could become brittle and prone to cracking. These issues aren’t always visible to the naked eye or detectable with simple dimensional checks. That’s where specialized inspection becomes important.

Taiwan is a major producer of fasteners, but its ability to check parts for heat treat defects is limited. This creates a slowdown in production. Manufacturers there need inspection systems that are both very fast and extremely accurate. Traditional methods (like manual sampling or basic eddy current testing) often fall short because they can’t provide full coverage or detect subtle deviations. This is where Mectron’s technology steps in.

How Mectron’s Differential Coil Works

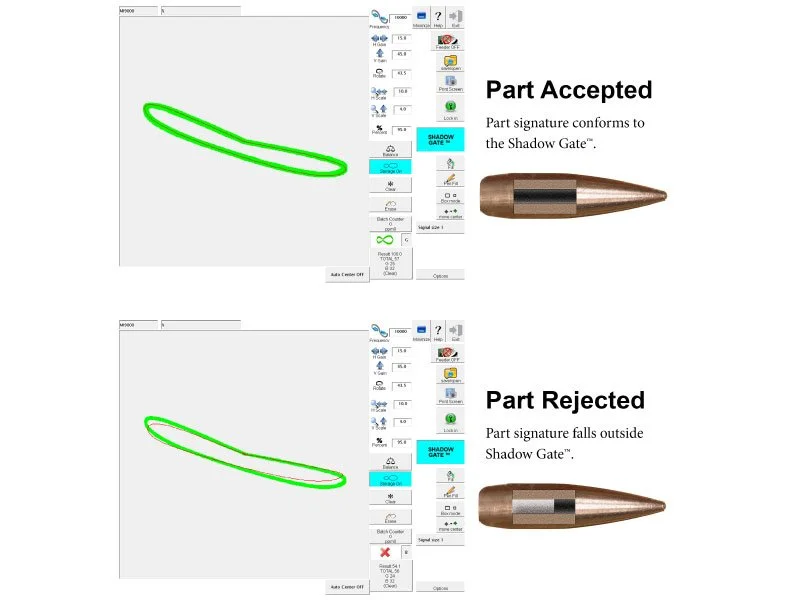

Our differential coil technology is integrated into every inspection machine we offer, including the Qualifier® series. This coil generates a magnetic field that interacts with the fastener’s material properties. As parts pass through the coil, the system captures a detailed “magnetic signature” for each one. Deviations in this signature (caused by variations in hardness, material composition or heat treat inconsistencies) are flagged immediately.

This method is non-destructive and operates at high speeds, which makes it perfect for inline inspection. For instance, our systems can process hundreds of fasteners per minute and provide real-time feedback without slowing down production. The differential coil is effective for identifying:

Inconsistent hardness levels across a batch

Material mixes (e.g., wrong alloy used)

Cracks or structural weaknesses induced by heat treating

Plating or coating variations that affect performance

Why This Matters for Taiwanese Manufacturers

Taiwan plays a large role in the global fastener industry, supplying high-quality parts to manufacturers around the world. But when local heat treat sorting capacity can’t keep up, some flawed fasteners may go undetected. Using Mectron’s differential coil technology gives producers the ability to inspect every single part, identifying hard-to-spot defects before they become a problem. This is especially important for fasteners used in safety-critical applications, such as automotive or aerospace, where failures are not an option.

Our systems easily integrate into existing production lines because they require minimal operator intervention. The differential coil’s sensitivity makes sure that even minor heat treat deviations are detected, reducing the risk of recalls or customer complaints. Our machines also include dimensional laser scanning and magnetic imagery. Together, these technologies give you a complete picture of fastener quality by connecting heat treat verification directly to full defect detection.

Real-World Impact

Consider a Taiwanese manufacturer producing bolts for electric vehicle battery modules. These bolts endure extreme stress and heat. Inconsistencies in their heat treatment could cause early failures, risking both safety and the manufacturer's reputation. Mectron's inspection systems allow producers to verify the hardness and material integrity of every single bolt, ensuring they meet strict industry standards and customer requirements.

The Mectron Advantage

What makes our approach different is how we examine the entire part. Many systems only check one characteristic at a time, which can miss important flaws. Ours brings together laser measurement and magnetic field analysis for a complete view. A good example is our Qualifier® Q-4000 system. It uses several lasers and eddy current technology together, finding size variations and material issues in a single pass. This dual approach is essential for heat treat verification, as it correlates surface features with underlying material properties.

Our differential coil technology is made for busy production floors. It's a hands-on answer for Taiwanese manufacturers who need to sort more parts. The coil is designed to sharply reduce false rejects and quickly adjust to different fastener sizes. This keeps your line moving fast without compromising on quality.

Conclusion

Verifying heat treatment is a decisive stage in making fasteners. For manufacturers in Taiwan and elsewhere, choosing inspection systems with integrated differential coil technology does more than pass quality audits. It secures your production process for the long term and guarantees dependable products. At Mectron, we build our machines to directly confront heat treat defects, giving you the clear results and assurance required to compete effectively.

If you’re looking to improve your heat treat sorting capabilities, explore how Mectron’s inspection solutions can bring clarity to your production line. Let’s work together to ensure every fastener meets its mark.