In the automotive industry, every bolt, screw and nut carries a weight far beyond its size. These components (the unseen connectors holding vehicles together) form the foundation of automotive integrity. When fasteners fail, the results extend beyond mechanical breakdowns to encompass safety concerns, financial losses and reputational damage. This reality places automotive fastener inspection at the center of manufacturing quality, transforming it from a final checkpoint to a central pillar of responsible production. At Mectron Inspection Systems, we recognize that in this field, there is no room for compromise.

The Unforgiving Mathematics of Fastener Failure

A single fastener represents a tiny fraction of a vehicle's composition, yet its failure can trigger consequences affecting millions of dollars and, more importantly, human safety. The global automotive industry faces increasing complexity with the transition to electric vehicles, new material combinations and demanding assembly processes. These developments have made comprehensive automotive fastener inspection increasingly vital for manufacturers who supply major automotive producers.

Traditional sampling methods (checking a handful of parts from a production run) once served as the industry standard. However, as assembly lines become more automated and quality expectations intensify, sampling reveals its limitations. One overlooked flaw in one unchecked fastener can disrupt an automated assembly process, halt production lines or worse, reach end users with potentially serious consequences. This understanding has driven the shift toward 100% inspection, where every component undergoes scrutiny before reaching customers.

The Multiple Dimensions of Fastener Integrity

Effective automotive fastener inspection addresses three fundamental aspects of component quality: dimensional accuracy, material integrity (including heat treatment) and surface perfection. Each element presents unique detection challenges that conventional methods often miss.

Dimensional Perfection Through Laser Measurement

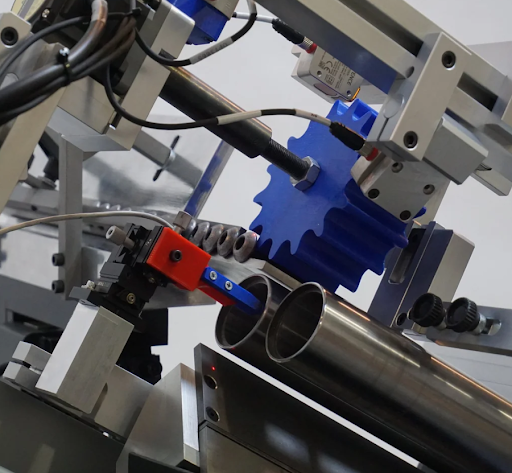

Dimensional defects represent some of the most common issues in fastener production. Bent fasteners, imperfect threads or out-of-spec dimensions can jam automated assembly equipment, creating costly production delays. The Mectron Qualifier® series addresses these concerns using an array of eight lasers that provide sixteen separate inspection points, achieving 360-degree coverage of each fastener.

As components travel down the V-track through the laser array, each inspection point covers the entire length of the fastener. This system can examine countless different part features with diameter repeatability of 0.01 mm. The technology identifies various dimensional problems, including deformed or bent parts, damaged hex heads, patented thread defect detection tools (for defects such as spiral, dented, drunken or roll-up threads) and feature deviations that could affect assembly or performance. For manufacturers supplying fasteners for automated assembly processes, this level of dimensional verification provides confidence that every piece will fit and function as intended.

Heat Treat Verification

Heat treatment represents one of the most important yet challenging processes in fastener manufacturing. This controlled heating and cooling process develops the mechanical properties that give fasteners their strength and durability. However, variations in time, temperature or quenching can produce inconsistent results. Under-hardened fasteners may lack required strength, while over-hardened ones could become brittle and prone to cracking. These flaws often remain invisible to visual examination yet can lead to catastrophic failures in application.

Mectron systems integrate differential coil technology specifically designed for heat treat verification. This technology generates a magnetic field that interacts with the fastener's material properties, capturing a detailed "magnetic signature" for each part. Deviations in this signature caused by variations in hardness, material composition or heat treat inconsistencies receive immediate identification. The system effectively identifies inconsistent hardness across a batch, material mixes (where incorrect alloys have been used), cracks or structural weaknesses induced by heat treating and plating or coating variations that affect performance.

This capability holds particular value for electric vehicle applications, where fasteners often face extreme stress and thermal cycles. Battery module bolts, for instance, must maintain their clamping force under varying temperature conditions. Inconsistent heat treatment could lead to early failures that compromise battery safety and vehicle performance.

Surface Flaw Detection

Surface defects (including cracks, voids and material inconsistencies) represent another category of flaws that can undermine fastener performance. Mectron systems combine multiple technologies to address these concerns comprehensively.

The MI9000 Magnetic Imagery™ system employs an advanced eddy current technique that provides complete metallurgical inspection as parts move through the system. Unlike conventional eddy current systems that provide only a peak value, Magnetic Imagery™ develops a full magnetic image of each part, creating a unique signature that reveals even subtle defects. This method identifies cracks, material mixes, conductive plating variations and hardness deviations through visual variations in the magnetic display.

For surface examination, vision inspection systems using CCD cameras deliver capabilities for identifying open burst cracks, recess imperfections and through-hole applications. When combined with the 360-degree laser array and Magnetic Imagery™ technologies, these vision systems contribute to a comprehensive inspection approach that addresses both external and internal defects.

Meeting Standards with Confidence

The regulatory framework governing fastener production continues to evolve, with ISO standards and OEM-specific requirements creating a complex compliance landscape. The International Organization for Standardization maintains specific standards for fastener inspection documents, including declarations of compliance and test reports. Many automotive OEMs have also developed their own specific requirements, with some mandating metallurgical testing on fastener products.

For fastener manufacturers, navigating these requirements while maintaining production efficiency presents an ongoing challenge. Mectron's integrated approach provides documented verification of quality, generating the data needed for compliance reporting. The system's ability to inspect every part for multiple defect types simultaneously helps manufacturers meet both general ISO standards and specific OEM mandates without sacrificing throughput.

Beyond Problem Detection

While defect identification remains the primary function of inspection systems, the business benefits extend further. Modern inspection equipment provides valuable data that manufacturers can use for process improvement. The information collected enables Pareto analysis, helping identify the most frequent defects and their root causes. This intelligence allows manufacturers to refine their production processes, addressing problems at their source rather than simply detecting them at the end of the line.

This aspect of continuous improvement supports quality management system requirements while driving down production costs and improving overall operational effectiveness. As David Gibson of Char-Tech explains, "The Mectron equipment is not only for shipping good parts in the box; they add value to the product".

The Evolving Role of Inspection

As automotive technology progresses, fastener inspection will continue to develop in importance and sophistication. The industry's movement toward electric vehicles, lightweight materials and increasingly automated assembly processes will place additional demands on fastener quality and reliability.

Manufacturers who invest in comprehensive inspection capabilities position themselves to meet these evolving challenges while strengthening their market position. In an industry where quality expectations only increase, the ability to guarantee component integrity provides a distinct competitive advantage.

Building Trust One Fastener at a Time

In the final analysis, automotive fastener inspection transcends technical specifications and compliance requirements. It represents a pledge to product integrity, customer satisfaction and ultimately, roadway safety. The connections fasteners create extend beyond metal components to encompass the trust between manufacturers, suppliers and end users.

At Mectron Inspection Systems, we build our technology around this understanding. Our integrated approach (combining laser measurement, magnetic imagery and vision systems) provides the multi-layered examination that modern automotive fasteners require. This methodology helps manufacturers produce components that meet the automotive industry's most demanding applications, supporting the vehicles that transport families, goods and communities.

In automotive manufacturing, fastener failure cannot be an option. With the right inspection partner and technologies, it does not have to be.