The SHOT Show isn’t just any trade show. It’s the center of the shooting, hunting and outdoor industry. From January 20–23, 2026, the Venetian Expo and Caesars Forum in Las Vegas will transform into a hub of energy, expertise and opportunity. Whether you’re a buyer, manufacturer or industry professional, here’s why you should be there and how Mectron Inspection Systems fits into the picture.

1. Unmatched Industry Networking and Deal-Making

The SHOT Show is the biggest gathering for people in the shooting, hunting and outdoor industries. It brings in buyers from across the U.S. and around the world. This event is a major opportunity for companies to make new contacts, see the latest products and form partnerships that help them grow.

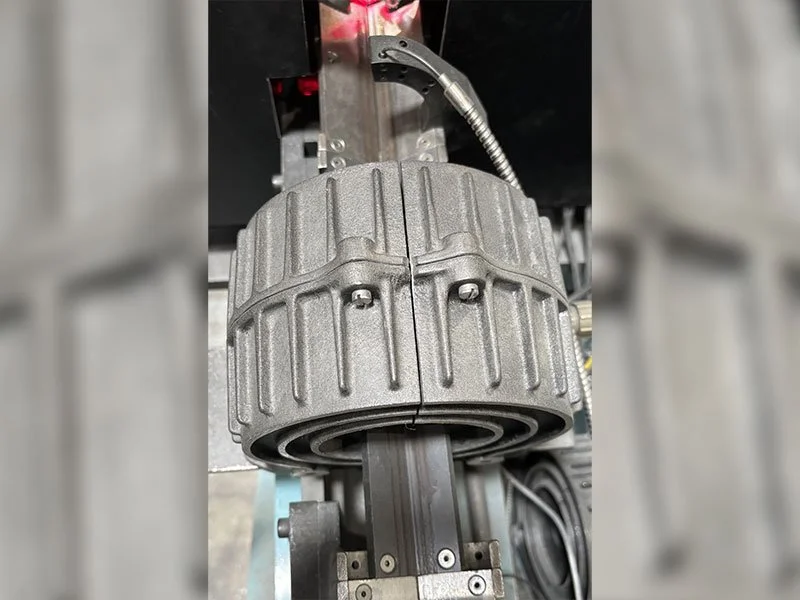

Mectron Inspection Systems, a family company with a long history, will be there. They will be showing their fast inspection machines. These machines work behind the scenes to check the quality of ammunition and fasteners, making sure they meet high standards. If you make or buy these parts, talking to Mectron could help you make your products more dependable.

2. Exclusive Access to Education and Trends

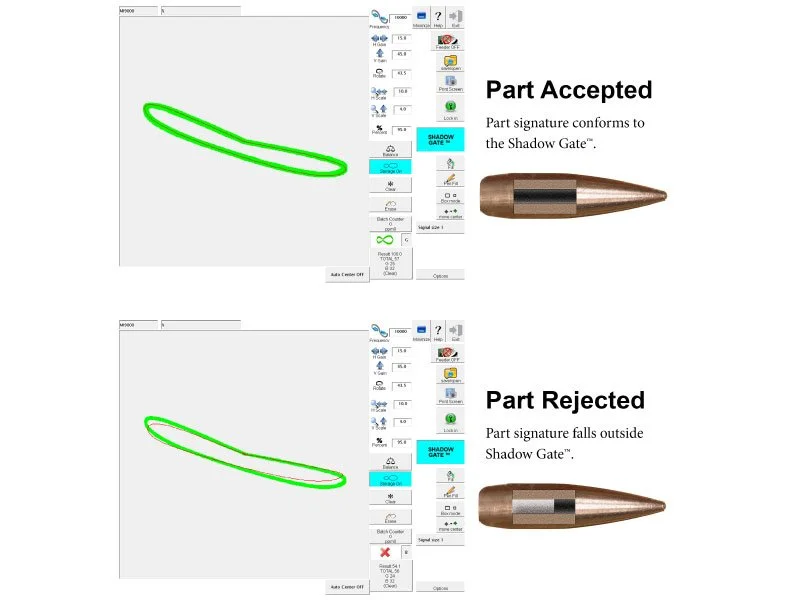

SHOT University provides classes to help store owners and shooting ranges succeed. The classes teach important topics like rules, online advertising, stock control and working with customers. For those who care deeply about quality, Mectron's skill in detailed part inspection fits right in with these lessons. Their systems, which use lasers and vision cameras to examine ammunition and fasteners, reflect the kind of attention to detail that industry leaders strive for. Learning about their technology could inspire new approaches to your own operations.

3. Discover Innovations Like Mectron’s Inspection Systems

The SHOT Show is known for guns and outdoor equipment, but it also features the tools that make these products work safely. For instance, Mectron brings machines that use lasers to check every angle and surface of ammunition and fasteners for flaws. These systems help manufacturers deliver products that meet strict standards, reducing the risk of defects. Seeing Mectron’s machines in person (like their Surface Qualifier) offers a hands-on look at how quality assurance can be integrated into production.

4. Experience the Energy of Las Vegas

Las Vegas is more than a backdrop; it’s part of the SHOT Show experience. The city ensures attendees can work and play with ease, from world-class dining and entertainment to convenient transportation options like shuttles and ride-shares. After days spent exploring the exhibit halls, unwind at networking mixers, happy hours or even the SHOT After Dark events at venues like OMNIA and JEWEL. The city's energy reflects the show's intensity, making it a perfect destination for productive business and enjoyable downtime.

5. Support Industry Advocacy and Growth

Revenue from SHOT Show directly supports the NSSF’s efforts in advocacy, compliance education and firearm safety programs. By attending, you’re contributing to initiatives that benefit the entire industry. Companies like Mectron embody this spirit of support. Their inspection systems help manufacturers adhere to regulations and quality benchmarks and create trust and safety across the supply chain.

Tying It All Together

For over 50 years, Mectron Inspection Systems has served key industries like aerospace and ammunition. Their exhibit at SHOT Show 2026 highlights their commitment to quality assurance, which is a key concern for attendees focused on reliability and performance. Mectron's technology helps manufacturers improve their processes and helps buyers find dependable suppliers, supporting the show's emphasis on excellence and innovation.